For anyone to grow in the manufacturing industry, the basics of machining should be fully understood. To understand the basics of machining is to understand precision machining.

CNC industries and many manufacturers if not all make use of precision machining. The precision machining to everyday tools.

Precision machining is an important part of manufacturing new technology hardware. The tools used to make them are made using precision machining.

What Is Precision Machining About?

All technical manufacturing processes need and make use of precision machining. That makes it an essential part of manufacturing and a crucial manufacturing instrument.

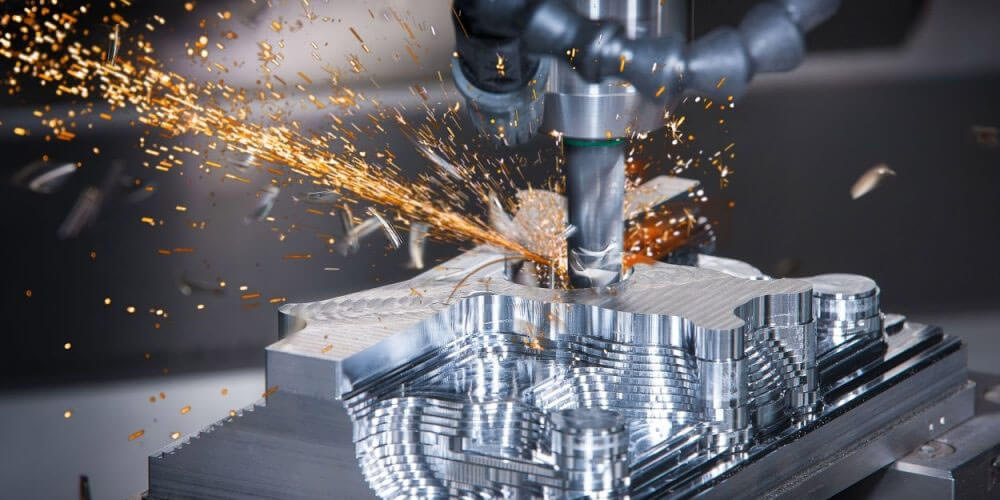

Precision machining is used to design tools, machines, and any other hardware. Best at shaping and reshaping gigantic material pieces, precision machining is the perfect tool for perfect finishing.

So, if you want your small parts to fit properly, all you need is a little precision machining, done. With precision machining, there is a very slim chance that your machined object will break.

Benefits of Precision Machining to Manufacturers?

Note: In most cases, the precision process is run by a computer-based machine. This is to make the manufacturing process easier and its components safer and comfortable.

1. It Ensures Quality

Most businesses run on one principle – the better the quality of the product, the more expensive it is. This means that to sell for higher prices and make higher profits, more quality materials are needed.

You have to ensure that your tools and components are of the best quality for you to sell them at a higher rate in the market.

With the precision machining process, you are assured of quality tools. The machines are usually software-based and computerized.

They are also automatic which makes them quick and easy to operate during operation. During operation, physical human strength is not the force that makes it work, but a programmed software.

2. Reduced Costs and Errors

Precision machining is also very useful to manufacturers who wish to reduce the cost of their products. While they reduce the cost of their product, they also limit the errors with precision machining.

If you want to get consistent in producing perfect tools and components, precision machining is the process to achieve that.

This is because precision machining is more accurate, and error-free than any human can be. The machining process is completed without error at a very high speed.

3. Smooth Production

With CNC precision machining production happens faster and smoother. More production means more money for the manufacturers.

And that explains why most manufacturers prefer to use computer-based programmed precision machining processes for their production instead of manual labor.

Using an automatic computer-based program is a better choice. This is because human labor can make mistakes or will need to rest once in a while, but machines do not need to stop.

4. You Save Your Materials

The main point of precision machining is the reduction of mistakes, costs, or materials. This machining process causes less wastage for individual products.

Without human error, this machining process saves you a ton of waste material which in turn saves you more time for more production.

Conclusion

Joining the league of established manufacturers in the market cannot happen without possessing the right tool – precision machining.